The Evolution of Sorbothane in Sports Medicine

Development of Sorbothane® – Studying Heel Strike

In 1975, material scientist Dr. Maurice Hiles embarked on a series of bold and fascinating human experiments to measure the effect that running and walking have on the human body.

Through his testing, Dr. Hiles took measurements at various positions in the human frame that confirmed the shock from heel-strike is not a smooth wave flowing through the body. It is rather a reverberation, like a shunting train, with successive sharp shocks transmitted rapidly up the skeleton and then radiating slowly in shear outwardly from the bone, through the surrounding soft tissues.

Not only do these rogue shock waves slow recovery; they can also contribute to pain and degeneration. Achilles Tendonitis, for example, was thought to be the result of the force of the foot hitting the ground causing micro tears in the muscle fibers and was often treated by raising the heel to relax the tendon. However, high-speed film shows that, at the instant of heel strike, tension in the calf muscles is not at its maximum. And a few milliseconds later, one sees the contraction wave appear. It is, therefore, far more likely that the damage is caused by the shear waves producing a whiplash effect in the soft tissue.

What is the best shock absorbing material for the harmful effects of heel strike?

Studies indicate that transient shock waves and high levels of acceleration may be detrimental to a normal body’s healing process. Heel strike can be harmful and may contribute to musculoskeletal degeneration and other disorders, such as:

- Aggravating pre-existing neuromuscular and skeletal disorders

- Contributing to the degenerative cartilage changes associated with osteoarthritis

- Loosening of prosthetic joints

- Be a factor in back and neck pain

- Pain beneath the heel

- Soft tissue sports injuries

- Lead to joint discomfort throughout the body

- Planter fasciitis

- Post-fracture pain

- Retardation of recovery from injuries to the spine and lower limbs – particularly those resulting from sporting activities

How Does Sorbothane Cushion Harmful Shock Waves?

Dr. Hiles’ studies have shown that human flesh could have a remarkable ability to absorb kinetic energy. In fact, shock wave readings as high as 5G at ankle level could become as low as 0.5G at teeth level. However, overuse, injury and normal aging severely diminish the effectiveness of the body’s own ability to handle harmful impact shock.

Conventional materials such as foam, soft rubber, silicon, sponge, felt and leather have been tested in cushioning impact shock waves but were proven ineffective. Either they do not reduce the level of deceleration or their wear characteristics rendered their life unacceptably short. One or two can increase reverberation quite substantially.

Accordingly, extensive research and development was initiated by Dr. Hiles and Sorbothane, a viscoelastic polymer, was the result – a unique material that reproduces the molecular structure and physical characteristics of human flesh.

Shock Absorption – The Sorbothane Difference

When used as a heel insert or insole, Sorbothane delays the deceleration peak and reduces it to an acceptable level. Similarly, the decay is also delayed and the reverberation is eliminated. Sorbothane is a material that provides comfort and helps protect the entire body from impact shock injuries. Sorbothane won’t bottom out, breakdown or lose its effectiveness – even after thousands of cycles.

Nike Studies Confirm Sorbothane Absorbs Up To 94.7% Of Impact Shock

Sorbothane is unique – because it reduces the force of the initial shock (the peak is a lot lower with Sorbothane) and also spreads the load over a longer period. Sorbothane absorbs more energy than competitive materials and, after compression, it returns steadily to its original position. Sorbothane fully and smoothly will return to its original shape after a measured delay. The delayed recovery rate of Sorbothane prevents the “backlash” of the shock waves. In 1980, the Sorbothane Heel Pad was featured in Nike running shoes called the “Equator.” Nike conducted studies that confirmed Sorbothane absorbs up to 94.7% of the impact shock from running.

Sorbothane Insoles Offer Impact Protection

The research, which revealed damaging shock waves that are transmitted through the skeletal structure on heel strike, also indicated the desirable properties of a cushioned pad.

- Initially, the impact of the heel on the ground has to readily deform and spread the load over a wider area.

- Then, on compression by the body’s weight, the pad must become progressively stiffer to halt the downward movement of the heel. During this deceleration, the pad has to dissipate the energy absorbed.

- Finally, the pad must return to shape at a rate slow enough not to exert a significant upward pressure when the foot is on the ground, but fast enough to regain its shape during the next step.

A material possessing these properties must act both as a viscous fluid and like a resilient rubber. Viscoelastic Sorbothane exhibits both fluid and solid properties.

Sorbothane is a synthetic material that has many of the properties of the body’s own energy-absorbing tissue and skin. Sorbothane is soft and is readily deformed, yet is capable of dissipating over 90% of the energy of deformation. Sorbothane also fully returns to shape once the deforming force is removed, and at the desirable rate between heel deceleration and the period of a step.

Sorbothane has this combination of unique properties due to the deliberate molecular-engineering in its synthesis. A viscous liquid contains long-chain molecules with attractive forces between them, which have to be overcome by the deforming force. Conversely, a resilient rubber is composed of a network of chains of low inter attraction, that quickly return to shape when removing the deforming force. Sorbothane has been designed to be in between these two properties. The polyurethane molecules exert a high damping action on being deformed but a loose network holds them together, which is sufficiently strong enough to return the material to original shape.

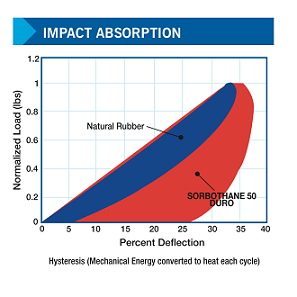

Best Impact Absorbing Material

This graph shows the high hysteresis necessary for efficient impact absorption. By comparing the area under the curves, it is clear that Sorbothane removes more of the impact energy from the system. Natural rubber is more elastic and returns energy to the system. High-energy return causes high rebound and increases the potential for damage.

Sorbothane Standards

APMA – Ensuring Quality

In 1986, Sorbothane was granted the American Podiatric Seal of Acceptance, which is an award given to shoes, socks, insoles, equipment and materials. This award is an honor, and is given granted to products found to promote good foot health.

100% Made in America

Since the beginning, Sorbothane Insoles have been made in the USA. Highly recommended by doctors, sports medicine specialists and professional trainers – Sorbothane Insoles have proven to be the best defense against foot pain and impact-related injuries.

Interested in learning more about Sorbothane? Contact us today or view more information on our site.